Products

IBR STEAM BOILERS

IBR also known as Indian Boiler Regulation

“THERMO” is IBR certified Boiler Manufacturer and offers high standard steam boilers of various types.

Products:

- THERMO-OILPAC

- THERMO-FIREPAC

- THERMP-HUSKPAC

- THERMO-WATERTUBE

THERMO-OILPAC :

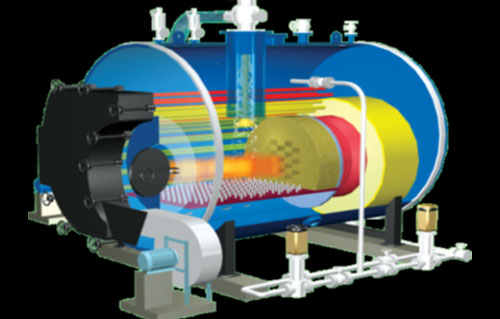

This 3-pass wet back design is developed by our inhouse team ensures maximum heat transfer area and to reduce the waste heat leaving the system. Comes with mono block or dual block burners imported from Italy.

This wet back design also ensures to reduce the fuel cost by at least 20%. The liberally sized furnace which is designed by taking radiation & convention into account helps in higher volume of fuel to burn ensuring higher efficiency and lower exit temperatures.

The burners used in the THERMO-OILPAC boilers are of REILLO or ECOFLAME make which are of high quality and international make. These burners are made in accordance with international standards.

THERMO-FIREPAC :

This type of boiler can be supplied in 2-pass & 3-pass design depending on customer requirements

The 2-pass design of fire Pac is a smoke tube boiler in which the flu gas is passed through tubes and water is surrounded around the tubes inside the drum, which will allow the heat to transfer from tubes to water which turns into steam.

The boiler has a furnace along the length of the boiler which opens to the front and rear tube sheets, boiler ERW tubes are fitted in between this tube sheet which opens to the smoke box, these smoke box at the rear end is used to guide the flu gas to 2nd pass, and the smokebox at front end is used to guide the flu gas to chimney inlet.

Features:

- Low stack temperature at boiler outlet

- Electrically driven water pumps

- Integral flu furnace

- Skid mounted

- Low-cost heating

- Higher Heat transfer rate

THERMO-HUSKPAC

This next generation huckpac is fitted with bubbling bed combustion gives higher residence time to complete combustion and giving higher efficiency. Turbulent mixing of air and fuel reduces the ash formation and settlement.

The complete unit is designed in accordance with latest IBR standards, pressure parts are calculated with various trail and error to choose exact dimensions. These designed pressure parts are then validated with FEM (Finite Element Analysis).

The complete final design is Simulated in 3D AutoCAD software for perfect fittings and to find any errors.

Features :

- Low-cost heating

- Rice Husk fuel firing

- Bubble bed design for higher combustion efficiency

- Design pressure ranges (10.54 kg/cm2 & 17.5 kg/cm2)

THERMO-WATERTUBE :

This is a hybrid water and smoke tube design made in accordance with IBR standards. The furnace is designed based on the principle of FBC (Fluidised Bed Combustion) in which the air is made to flow by FD fan over the bed with the help of various nozzles places on the bed.

The water wall is used to circulate water through the tubes to achieve water circulation, this water wall is placed above the furnace chamber where the FBC combustion takes place. The heat transfer takes place in water wall through radiation between flu gases and water wall, conduction through tube thickness and convection between tube and water inside making it raise its temperature.

The steam drum or shell assembly is places after the water wall which is a single pass design.